About us

Business

Products

Quality(QM)

Community

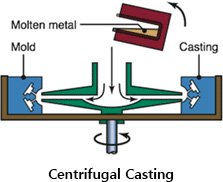

Centrifugal casting

What is Centrifugal Casting?

This method is a horizontal and vertical casting method for manufacturing tube-type products according to the rotating axis of the mould by injecting a metal solution into a mold that rotates at a high speed of 300 to 3,000 RPM to obtain dense tissue by separating impurities by gravity. We develop vertical centrifugal casting construction (patent construction) for manufacturing ring-type products to respond to customers' needs.

※ When pouring molten metal, the mold is rotated at high speed and cast using its centrifugal force.

※ It is easy to remove metal inclusions due to fine tissue, no pores, and non-gravity differences.

-

Vertical type centrifugal casting PIM VINA

Vertical type centrifugal casting PIM VINA -

Horizontal centrifugal casting

Horizontal centrifugal casting

Advantages

- Easy manufacturing process

- Superior mechanical properties

- High productivity

- Appropriate to flange shaped and hard cutting metal products

- 15~20% lower cost comparing to horizontal type

- Possibility of making small inside diameter (min, 20mm)

- No internal defects

Typical material & properties

| Material | Composition | Y.S.(MPa) | T.S.(MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|---|

| GHS-4 | Fe-12Cr-40Ni-6Mo | 700 | 900 | 3 | 370HV |

| DIN1.4091 | Fe-36Cr-16Ni-2Mo-1Mn | 650 | 850 | 2 | 350HV |

| DIN1.4509 | Fe-18Cr-Ti-Nb | 300 | 530 | 2 | 160HV |

| DIN1.4845 | Fe-25Cr-21Ni-1Si | 220 | 550 | 25 | 150HV |

| PL33 | Fe-34Cr-3Mo | 300 | 630 | 2 | 350HV |

| PL23 | Fe-19Cr-13Ni | 350 | 650 | 8 | 240HV |

Process

Process

Centrifugal Casting

-

01Raw Materials

-

02Melting

-

03Holding & Alloy adjustment

-

04Bottom pouring

-

05Casting

-

06Machining

-

07Finished parts

Application

-

Spool with Inner oil/air hole

Spool with Inner oil/air hole -

Solenoid Valve Part with Two-material

Solenoid Valve Part with Two-material -

Stainless Valve with round wall

Stainless Valve with round wall

Facility

-

Furnace(300 kg-1set)

Furnace(300 kg-1set) -

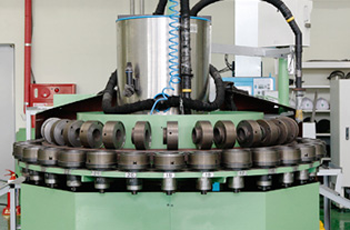

Centrifuge(32cavity-2sets, 26cavity-1sets)

Centrifuge(32cavity-2sets, 26cavity-1sets) -

Sulfurizing machine(Single-function panel-13set)

Sulfurizing machine(Single-function panel-13set) -

MCT Equipment(6 sets)

MCT Equipment(6 sets) -

CNC Equipment(44set)

CNC Equipment(44set)